Artificial intelligence (AI) is revolutionizing manufacturing, yet many manufacturers struggle to harness its full potential. While discussions often focus on incremental improvements like predictive maintenance, these use cases merely scratch the surface.

Imagine AI not just optimizing existing workflows but completely transforming factory operations. This vision is now a reality. Today, manufacturers can reimagine their operations with tools like digital twins and industrial copilots, driving smarter processes, enhanced productivity and novel approaches to manufacturing.

Todd Edmunds, Global CTO for Smart Manufacturing at Dell Technologies and Himanshu Iyer, Principal Product Marketing Manager, Manufacturing Industry at NVIDIA, are excited about a game-changing strategy for plug-and-play AI use cases: AI “blueprints” developed and deployed with a flexible AI engine. This strategy can deliver powerful but easily deployable AI outcomes instantly, allowing manufacturers to dream bigger and act faster.

Unlocking transformation: Simplifying manufacturing AI

When it comes to AI in manufacturing, discussions often start with predictive maintenance. It’s a natural entry point as it helps prevent equipment failures and streamline processes. But focusing only on predictive maintenance is ignoring the full potential of AI.

Imagine a factory so intelligent that it seamlessly integrates supply chains, operations, maintenance and production schedules in real time. This isn’t a distant dream; it can be implemented today.

The traditional approach to AI in manufacturing often involves building custom applications from scratch, which is a slow, resource-intensive process. This leads many manufacturers to stay reactive, focusing on diagnostic tools or small-scale optimizations. Enter the AI Blueprint, a game-changing methodology designed to simplify implementation, accelerate development and move manufacturers beyond outdated systems.

“The AI Blueprint is a paradigm shift,” says Edmunds. “It allows manufacturers to easily unleash powerful tools to help turbocharge their operations using plug-and-play capabilities like custom factory virtual experts, real-time production insight video analysis and full industrial robot digital twin simulations. It empowers manufacturers to reimagine their processes, cut costs and unlock unlimited innovation.”

This transformation hinges on powerful processing and advanced software — technologies now accessible through the Dell AI Factory with NVIDIA and NVIDIA’s cutting-edge support for AI Blueprints. In August 2024, Dell and NVIDIA announced a joint initiative to streamline AI deployment, making it easier for manufacturers to adopt solutions tailored to their challenges.

“Blueprints turn ambitious goals into achievable results,” explains Iyer. “They eliminate friction, enabling factories to harness data and tackle issues like waste, supply chain disruptions and inefficiencies head-on.”

The potential is immense. By 2035, AI-driven advancements are projected to add up to $3.78 trillion to the manufacturing industry. Innovations like digital twins and AI copilots will play key roles in this revolution.

“Manufacturers now have the ability to address their most complex challenges,” Edmunds adds. “From supply chain and operations to maintenance and production changeovers, AI opens doors to solutions that were previously unattainable — or even unimaginable.”

Building blocks for GenAI applications

So, how does it work? The NVIDIA Blueprint is a reference workflow that provides manufacturers with building blocks for creating generative AI applications. Instead of starting from scratch, manufacturers can integrate their own data into the Blueprint to customize workflows for their specific needs. This approach accelerates development, reduces complexity and enables faster implementation.

“With NVIDIA AI Blueprints, manufacturers can harness their vast data in ways that weren’t possible before,” explained Iyer. “We now not only have access to the data but also innovative ways to process and leverage it for AI and generative AI applications.”

And now available is the NVIDIA AI Blueprint for video search and summarization to unlock insights from archived or live video streams. When combined with Dell’s AI Factory — a comprehensive and secure AI “engine” that integrates Dell’s compute, storage and services with NVIDIA’s advanced AI infrastructure to develop, deploy and scale AI applications — manufacturers gain the tools needed to achieve scalable, transformative AI applications.

Exciting use cases emerge

While the opportunities are endless, we explore two use cases — digital twin simulations and industrial co-pilots — to showcase what’s possible with a scalable strategy and infrastructure.

1: Factory virtual experts/Industrial copilots: Large language models (LLMs) for your factory

Factory virtual experts or industrial copilots are AI assistants that can be trained on specific manufacturing plant data. They are then used to provide real-time insights into processes, production schedules and decision-making to enable smarter and more informed operations.

Imagine an AI assistant that ingests manuals, production schedules and real-time factory data. With a simple query like, “Build me a dashboard that shows current production rates and forecasts how changes in suppliers would affect output,” the copilot delivers actionable insights instantly.

These copilots unlock smarter workflows, predictive insights and streamlined operations. By centralizing and simplifying complex data, they empower manufacturers to achieve faster, more efficient operations while minimizing errors and delays.

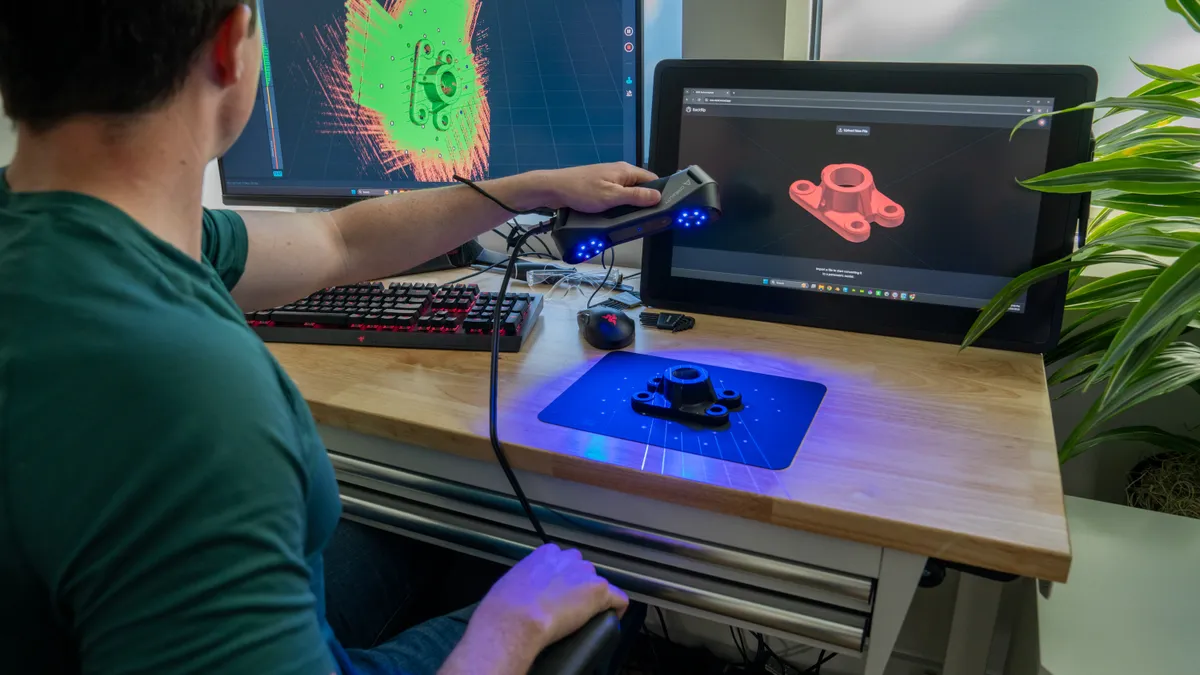

2: Digital twins: Visualizing, simulation and optimizing factory operations

Digital twins create virtual replicas of factory operations, enabling real-time simulation, visualization and optimization. They use live data to reflect current conditions and simulate potential changes, helping manufacturers anticipate challenges and refine processes.

Digital twins are poised to drive massive ROI — the market for digital twins is forecast to grow at a CAGR of 39.8%, reaching €242.11 billion by 2032. This technology enables manufacturers to fine-tune energy consumption, reduce waste and even meet sustainability targets.

Imagine a car manufacturer using NVIDIA Omniverse digital twins to redesign its factory for next year’s models. By simulating layout changes, testing new workflows and predicting potential risks, the company can optimize its operations before implementing physical changes.

“We’re talking real-time optimization at an ecosystem level, not just small tweaks,” emphasized Edmunds. “With digital twins, factories can elevate efficiency by 25% or more while reducing carbon emissions for long-term sustainability.”

As technology evolves, new opportunities emerge. For example, announced at CES 2025, NVIDIA Cosmos™ and Mega can help further simplify AI for manufacturers by accelerating the research and development of physical AI, such as robotic systems for manufacturing factories and warehouses.

Key components for AI success

Transformative AI solutions like digital twins and industrial copilots require more than ambition. Manufacturers need the right tools, technology and expertise to harness their data and achieve scalable results, including:

- Blueprints: NVIDIA Blueprints offer modular, standalone workflows that manufacturers can customize by integrating their own data. These plug-and-play workflows eliminate the need to build AI applications from scratch, speeding up implementation.

- Data: Dell Technologies’ smart manufacturing enterprise edge capabilities help manufacturers get factory data in real time, repeatably and at a global scale to accelerate all use cases, including digital twins.

- Workstations: Dell Precision Workstations have AI capabilities built-in and provide the computing power needed to run advanced AI workflows, enabling manufacturers to analyze and act on large datasets efficiently.

- GPUs: NVIDIA GPUs deliver the high-performance processing essential for scaling AI solutions while maintaining speed and accuracy.

- Expertise: Blueprint bridges skill gaps by offering workflows that don’t require in-house AI teams. With the right partnerships, manufacturers gain the developer support needed to deploy and scale advanced AI applications effectively.

This combination of components ensures manufacturers can harness their data and unlock the full potential of AI in manufacturing.

Imagine it, create it

With AI-powered tools like digital twins and factory virtual experts and copilots, and the infrastructure provided by Dell Technologies and NVIDIA, factories can transform into dynamic hubs capable of meeting today’s demands and anticipating tomorrow’s challenges.

Connect with Dell Technologies and NVIDIA to reimagine what’s possible in manufacturing. The tools to transform your vision into reality are here — what will you create?