Many manufacturers think of noncompliance costs in simple financial terms, but they are difficult to quantify and include lost market access and opportunities, inefficiencies, and reputational damage.

Your approach to compliance determines your program’s quantitative and qualitative costs, and there are two options: reactive and proactive.

“Reactive” product compliance refers to not acting on compliance until asked to do so (e.g., customer data requests, product seizures at the border), leading to higher costs.

In contrast, “proactive” product compliance acts before a need arises. For example, following market headwinds and reacting before a law is enacted, or before regulators or customers request data.

Why do manufacturers take a reactive approach?

- Regulatory complexity

- Ineffective product compliance practices

- Not fully understanding the consequences

1. Regulatory Complexity

Without support from regulatory experts, manufacturers frequently don’t know how expanding requirements could affect them, or even that requirements exist or have changed.

These challenges grow as manufacturers move into new markets. Regulatory requirements vary by region, and they might not realize that they were in scope of a regulation. The World Trade Organization (WTO) calls these “technical barriers to trade.”

2. Ineffective Product Compliance Practices

Product compliance is not a single activity or project, nor is it ever “finished.” Instead, it includes:

- Effective internal policies and procedures that communicate, internally and externally, company directives and expectations;

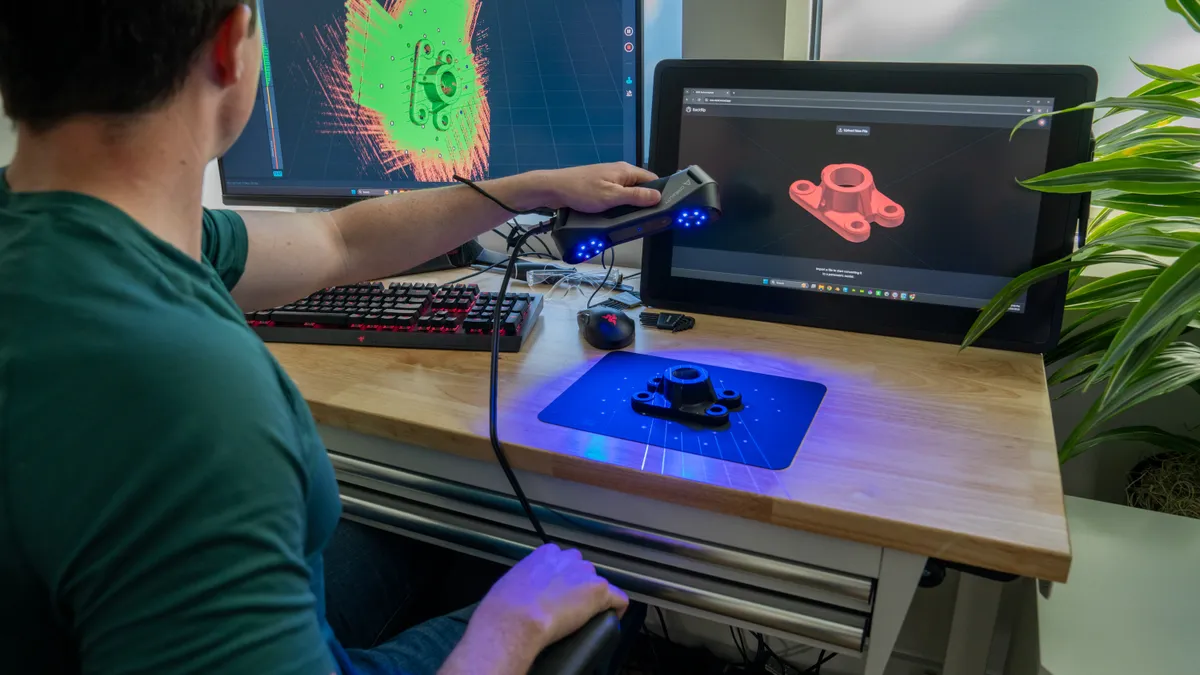

- Consistent methods, including tools and third-party resources, for collecting, managing, and using compliance-related data and documents;

- Product design processes that identify requirements, qualify product designs before production, and maintain compliance through regulatory changes.

When manufacturers do not develop a solid program, they struggle to demonstrate due diligence and keep up with regulator and customer data requests.

3. Minimal Awareness of Noncompliance Consequences

Fines and regulatory penalties are the most obvious noncompliance cost but there are other risks, including:

- Missed market opportunities (e.g., new markets, procurement opportunities)

- Forced product reformulation/redesign

- Not responding quickly or accurately to customer or regulator requests for information

The Real Costs of Reactive Compliance

Reactive compliance may initially seem less costly, but it creates expensive long-term challenges by negatively impacting sales, customer loyalty, and future orders while raising the risk of legal implications.

Let us look at the four challenges stemming from reactive compliance:

- Market access

- Time

- Data and documentation risks

- Reputation

1. Market Access

Reactive compliance can affect sales and delivery to regulated markets:

- Prohibition of delivering products to regulated markets

- Loss of sales opportunities

Reactive compliance can immediately affect market access — nonconforming products can lead to investigations, fines, and costly redesigns. Additionally, more countries are requiring compliance documentation BEFORE a product can be considered for import, potentially creating denied shipments and additional storage or transportation costs.

But a reactive compliance program also has an opportunity cost. Customers increasingly want to know suppliers are compliant before buying from them and will exclude manufacturers without evidence of compliance.

2. Time

Time is money and you waste both when you react to compliance requirements after designing and producing your product.

Manufacturers that don’t proactively gather data scramble to find it when a customer or government agency requests it. If they purchased large lots of components or a “last time buy,” the supplier may be unable to provide data. Additionally, if suppliers are not contractually obligated to provide data, you may have to conduct costly product testing yourself.

A proactive approach obtains data upfront, even during the design phase, to ensure new products are compliant, saving time and minimizing “surprises” and nonconformity risks.

Proactively collecting data also allows you to identify components that may become obsolete due to pending regulations, providing manufacturers with more time to plan for, and avoid, disruptions.

3. Data and Documentation Risks

A reactive approach to data and documentation creates risks and inefficiencies, including:

- Surprises and forced redesign as vital documents are not collected and validated in advance or centrally accessible

- Wasted time as manufacturers must manually look up every part in a product

- Confusion and conflicting data as multiple systems create numerous fields for the same data point

- Version control issues and siloes if employees work out of different files and rely on outdated information

4. Reputation

Reactive compliance can also damage your reputation because:

- Nongovernmental organizations (NGOs) often investigate and uncover noncompliance

- Government agency investigations or actions from consumer watchdog groups lead to investors not wanting to invest

- Original equipment manufacturers (OEMs) don’t want noncompliance risks because legislation often requires supplier due diligence

- Noncompliance jeopardizes on-time delivery for customers, which could lead to lawsuits for breach of contract and loss of business

- If consumers believe a manufacturer treats the environment or communities poorly, they won’t buy from them

The Benefits of Proactive Compliance

With proactive compliance, manufacturers avoid significant risks. Improved business continuity results from:

- Streamlined product importation with minimal disruption from regulatory authorities and procedures

- Better tools to anticipate and manage component obsolescence

- Increased customer confidence in business practices and on-time delivery

- Efficient employee utilization and faster responses to regulatory and customer data requests

Proactive compliance lowers the risks (financial and otherwise) for manufacturers. Through proactive compliance, they can design safe and sustainable products, better meet customer and regulatory demands, and, ensure long-term business continuity.