Art Figueroa is the SVP of global operations at Smith & Associates. Opinions are the author’s own.

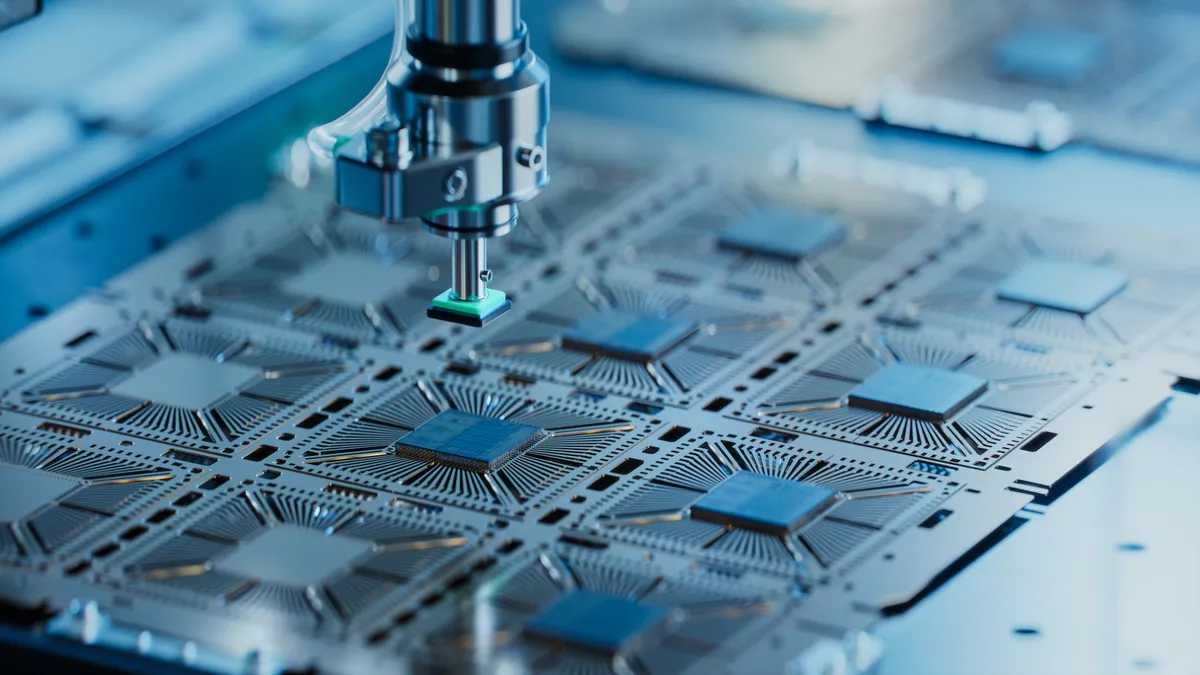

The chip sector underpins so much of our lives and is crucial to ongoing technological advancement from the Internet of Things (IoT) and 5G to artificial intelligence, consumer electronics, healthcare, vehicles and beyond. The world as it currently exists cannot function without semiconductors, with a single smartphone having around 160 different chips and hybrid electric cars including up to 3,500.

As a result, semiconductor production has increased exponentially. In 2022, the global chip market totaled $574.1 billion compared to $335.2 billion in 2015, according to the Semiconductor Industry Association.

The importance placed on both chips and sustainability today has caused many to turn an eye toward the semiconductor industry. Chip manufacturing is resource intensive and has a significant carbon footprint. It uses large amounts of water, consumes vast amounts of electricity and requires gases that can produce hazardous waste.

Sustainability in the chip industry is becoming critical. Greater effort has been exerted to find ways to minimize the environmental impacts of chip production as technology companies work toward loftier environmental, social and governance goals. It will be equally important for those who participate in the supply chain to implement changes to help alleviate the industry’s environmental impact.

Taking action by minimizing your carbon footprint

If your company is looking to become more sustainable, the first step is evaluation. When you have a global company, there are certain variables and factors that are out of your control. However, you can identify “low-hanging fruit,” or areas of the business where positive changes could most easily and inexpensively be made. These changes are an investment not only in our future but also in your company’s brand and reputation.

To get started, it is helpful to establish benchmarking metrics to measure a company’s sustainability progress. Start a companywide sustainability group with people from across departments to conduct an audit and find opportunities and priorities where you can make impacts in these areas.

Identifying any certifications in your industry that can motivate and guide improvements can further help you confirm your adherence. For example, the ISO 14001 standard helps companies and organizations by providing practical tools to manage their environmental responsibilities.

Possible areas to implement “greener” practices include:

- Streamlining packaging and eliminating excess waste.

- Decreasing your transportation footprint. This includes improving shipping efficiency by planning in advance to keep orders timely and prevent the need to express-ship products via air freight, which is very fuel intensive. Efforts to onshore chip manufacturing through the U.S. CHIPS and Science Act can also help decrease your carbon footprint from transportation.

- Lowering electricity usage by installing solar panels or adding LED and motion-sensor office lighting.

- Minimizing water use where possible.

- Eliminating the use and generation of hazardous chemicals.

Current initiatives to improve sustainability in the chip supply chain

Major chipmakers are prioritizing sustainability as they plan construction on new fabs. Samsung, for example, has rolled out a new environmental strategy with plans to achieve net-zero emissions by 2050 and prioritize water conservation. Intel recently committed to net-zero greenhouse gas emissions in its global operations by 2040, and is aiming to achieve 100% use of renewable electricity in 2030. Furthermore, OEMs, such as Apple, are putting pressure on suppliers to support their sustainability goals, including adhering to environmental policies and providing greater supply chain transparency.

The industry continues to make efforts toward better measuring and tracking carbon emissions throughout the chip supply chain. For example, Belgium-based semiconductor research accelerator Imec has formed the Sustainable Semiconductor Technologies and Systems research program to bring together stakeholders of the semiconductor value chain, including Microsoft. The program emphasizes sharing emissions data across the entire manufacturing lifecycle and across the supply chain, with the aim of using the combined knowledge and expertise to implement more sustainable solutions.

There is increasing pressure from stakeholders to incorporate environmental accountability into business models to achieve ESG goals as sustainability continues to be a vital issue. Greening the semiconductor supply chain is an ongoing challenge and process, but it is promising to see that companies are prioritizing greener practices and the beginnings of metrics standardization across the industry. In the long run, investing in sustainability is a high-return investment for everyone along the supply chain.