Dive Brief:

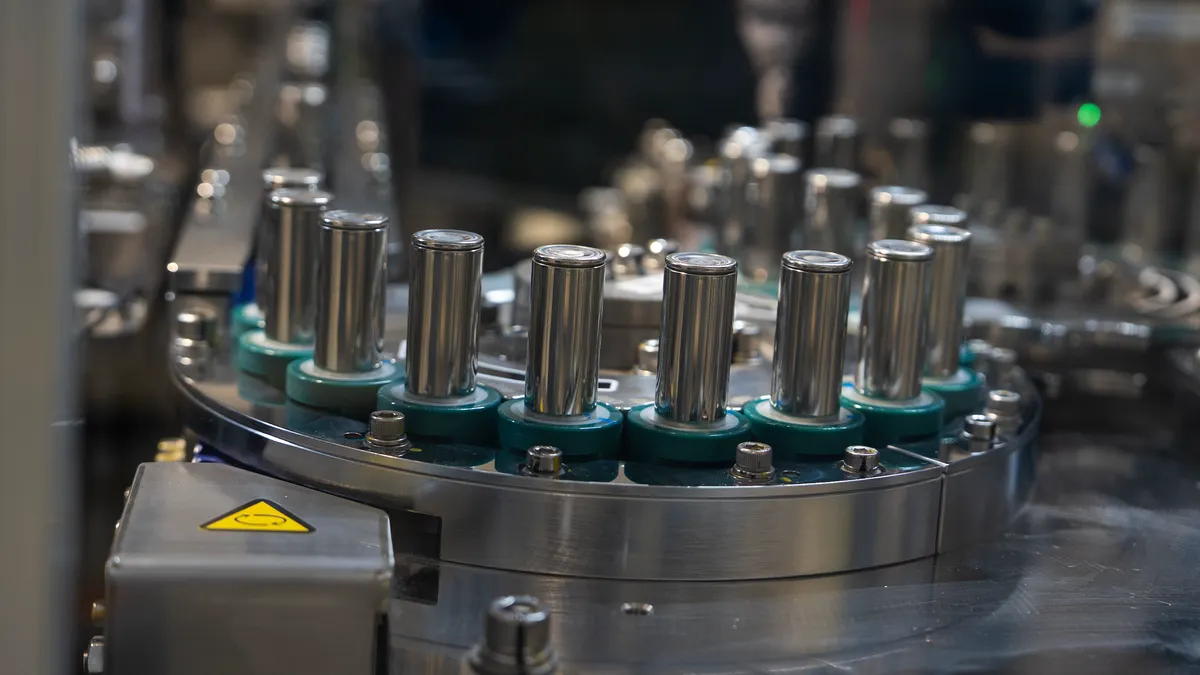

- Panasonic Energy Co. has officially opened its lithium-ion battery factory for electric vehicles in De Soto, Kansas, and has started mass production of 2170 cylindrical lithium-ion cells at the plant, the company announced in a July 14 press release.

- The company is targeting an annual production capacity of approximately 32 GWh in Kansas once the plant is fully operational. It will help Panasonic meet growing demand from its automotive customers in North America as they build more EVs.

- The plant is Panasonic's second U.S. battery manufacturing facility and the two plants boost the company’s total EV battery U.S. production capacity to approximately 73 GWh a year. Panasonic’s other battery factory in Sparks, Nevada, began operation in 2017 and currently supplies cylindrical cells to Tesla.

Dive Insight:

Panasonic's Kansas battery plant spans roughly 300 acres and is the size of more than 225 American football fields, according to the release. The $4 billion battery production facility is the largest economic development project in Kansas state history and is expected to create up to 4,000 direct jobs and approximately 8,000 jobs in total, including those in supplier and related industries.

“The opening of our Kansas Factory marks a major milestone in our journey to scale advanced battery production in the United States,” said Kazuo Tadanobu, CEO of Panasonic Energy, in the release. “This facility represents not only our commitment to the region but also a foundation for long-term collaboration and innovation in the U.S.”

Unlike Panasonic’s battery facility in Nevada that supplies cells exclusively to Tesla, the Kansas plant is “independent and designed to serve multiple customers,” a Panasonic spokesperson said in an email to Automotive Dive.

Panasonic says the project represents its long-term commitment of investing in and advancing the EV industry in North America. The company also plans to adopt a “dual-region model,” supplying batteries to global automakers from factories in Japan and North America.

The current generation of 2170 cylindrical cells Panasonic is manufacturing at its plant in Osaka, Japan, use advanced materials to improve battery performance by approximately 5%, according to the release. Panasonic plans to produce these same cells in Kansas. The company spokesperson said the 2170 cells manufactured in Kansas will be optimized to meet “the range, capacity, and demand of North American OEMs.”

Panasonic’s battery plant in Nevada is one of the largest lithium-ion battery manufacturing sites in North America in terms of output, according to the company. The plant employs over 4,000 people and has supplied over 11 billion cylindrical cells to date. Using its learning from operating the Nevada facility, Panasonic aims to achieve stable mass production in Kansas at an early stage, the release states.

Although some media outlets have reported this week that Panasonic is delaying battery production in Kansas due to falling EV demand, the company says it remains committed to the North American market and the future plans for the factory remain in place. A spokesperson said the company maintains “strong partnerships with a diverse range of automotive OEMs.”

“We have seen 11% growth in US electric vehicle sales in Q1 this year compared with last year,” a Panasonic spokesperson said in an email. “We're here for the long-term and are prepared to grow our production capacity in response to demand.”

Outside of Tesla, Panasonic’s battery customers include EV maker Lucid for the Air sedan and Gravity SUV models. The company is also collaborating with Subaru to supply batteries for its future EVs.

As of March, Panasonic says its batteries have been used to power around 3.7 million vehicles and the company has supplied roughly 19 billion cells to EV manufacturers.