Brian M. Legan is the EY Americas industrial products leader of advanced manufacturing and mobility. Opinions are the author’s own.

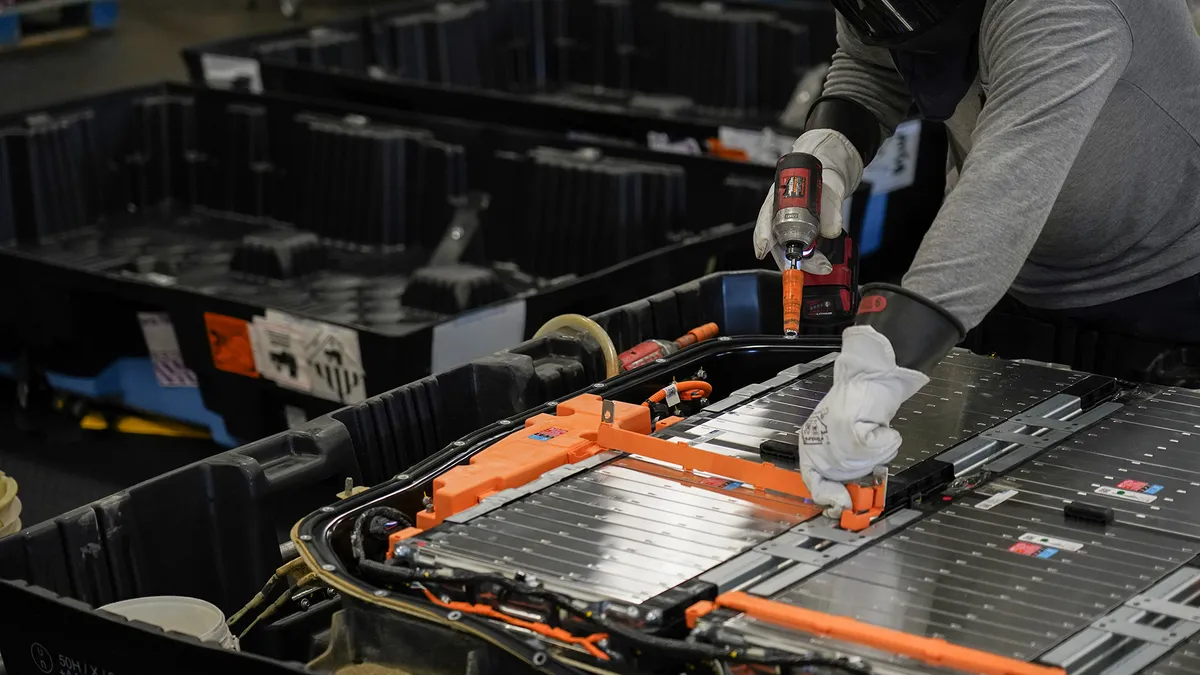

As the advanced manufacturing industry hurtles towards an era of unprecedented digital transformation, automation and artificial intelligence, one critical factor stands out: the importance of data.

It’s the lifeblood of our digital age, akin to the nutrients we consume daily. But just like our physical health, the quality and quantity of data we “consume” significantly impacts business performance.

According to a September 2023 EY survey, 84% of employers expect to implement generative AI within the next 12 months. Further, The Economist found that about two-thirds of companies have placed an AI-related job ad and about 25% of venture deals by S&P 500 companies involved AI startups, an increase from 19% just two years ago.

Despite these investments, companies are still neglecting their nutrition plan — or “data diet” — that will feed AI and ultimately influence performance.

The data deluge: a blessing and a curse

Industrial internet of things, smart factories and interconnected products have ushered in an age of data abundance. Manufacturing companies generate more than 1.8 million terabytes of data each year.

This is expected to grow exponentially as more devices and sensors connect to IIoT, yet many companies lack a plan to collect, analyze, manage and monetize data. Complicating matters are the array of fragmented legacy systems, such as enterprise resource planning, manufacturing execution systems and product lifecycle management, present in many companies.

Leading challenges that manufacturers face in getting more value from data include extracting it from legacy systems, a lack of data analytics skills and the integration of data from different sources. As a result, data is often left to languish in the silos that collected it, leaving companies without the valuable insights that could generate much-needed cost savings or new revenue streams.

This deluge can overwhelm even the most sophisticated algorithms. Data quality, veracity, accuracy and trust will ultimately be the key factor behind performance.

To ensure AI engines perform optimally, organizations need an effective recipe for enterprise data management and a leader (or “chef”) who has clear responsibility and accountability.

The importance of data governance

The role of the chief digital officer — the “master chef” — is expanding as it takes on heightened importance. CDOs are integral for developing and implementing effective data governance and leading cultural transformation, as traditionally data was IT’s responsibility. In fact, a recent survey by the EY Center for Executive Leadership found that the number of Fortune 100 CDOs has increased 1,300% in the past decade.

Challenges like data quality, integration, security and management prevent manufacturers from fully leveraging the potential of data to improve efficiency, quality, innovation and customer satisfaction.

Data governance establishes clear rules and protocols to ensure the adequacy, quality and freshness of proverbial ingredients in the pantry while also describing what data is needed, by whom, for what purpose, in what form, and to what frequency and precision.

Quality vs. quantity: striking the balance

In the quest for data-driven decision-making, there’s temptation to prioritize quantity over quality. Organizations collect everything they can — sensor readings, production logs, customer interactions — without considering the value of the data.

Just as a balanced diet requires essential nutrients, AI systems thrive on high-quality data. If data is riddled with inaccuracies, biases or noise, AI models will falter. Some data is simply empty calories that result in bloat, creating a performance detriment rather than an advantage.

Data sourcing and cleansing

The myriad of legacy systems and applications can result in stale, spoiled data. Just as a chef sources the best ingredients and washes vegetables before cooking, organizations must cleanse data by removing duplicates, correcting errors and validating sources.

According to EY, more than 50% of senior executives identify data management and analytics as a top priority. However, only 17% of employees and 22% of employers prioritized training in generative AI-related skills in 2023.

Data integration

Just as sweet, savory, spicy and sour work together, integrated data fuels AI models. Silos are the enemy, and seamless integration is the goal. Recent EY analysis showed that organizations that adopted a data fabric strategy found it requires less human intervention to analyze and manage data.

A business data fabric can be used to decouple data consumption from disparate data repositories and work across silos to pull in data that can be scaled and analyzed. It also enables companies to create true economies of scale, reduce costs and apply speed to the organization’s digital transformation.

It stitches together disparate databases, making a single view of enterprise-wide data accessible via just about any tool of choice. Data fabrics can also minimize replication through virtualization, giving users speedy access to high-trust raw data that resides in its native state.

Nutrition plan

Now, let’s feed our AI. In addition to implementing high-quality large language models trained on volumes of data and parameters, incorporating retrieval-augmented generation can help keep things fresh. RAG can improve the output of an LLM by referencing an authoritative body of knowledge outside of its core training data sources, incorporating the latest research, citing sources of information and generating a tailored, up-to-date response.

Nourishing AI for success

On the grand banquet table of industrial IoT, automation and AI, remember, you are what you eat! A healthy data diet and nutrition plan fuels innovation, drives efficiency and propels us toward Manufacturing 4.0.

So, let’s savor quality data, build muscle in data literacy through regular exercise and training and avoid indigestion from data overload.

Bon appétit!