Dive Brief:

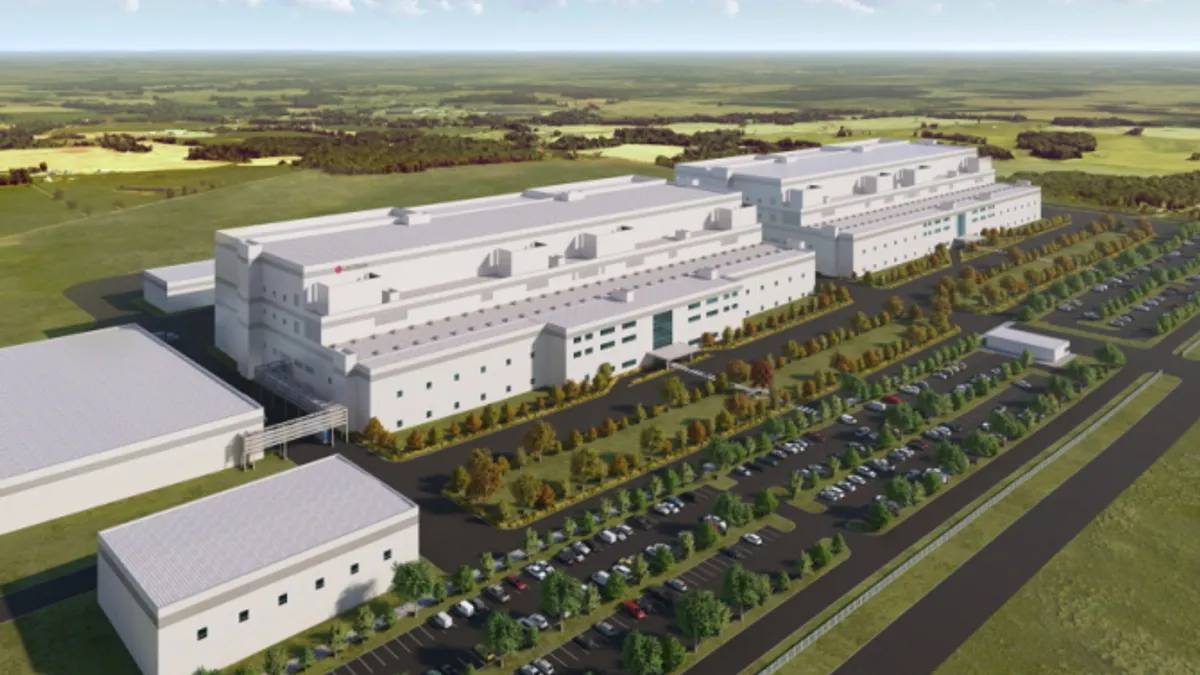

- South Korea-based LG Chem plans to build a $3.2 billion cathode manufacturing facility in Clarksville, Tennessee, marking the largest foreign direct investment in the state’s history.

- The facility will produce EV battery materials and is expected to make 120,000 tons of cathode material per year by 2027, enough to power batteries in 1.2 million EVs, according to an LG Chem press release.

- Construction of the facility will begin in Q1 of next year, with mass production set to start in the latter half of 2025.

Dive Insight:

LG Chem, one of South Korea’s largest chemical companies, has pivoted production towards the U.S. as it ramps up its battery materials business. The Tennessee facility allows LG Chem to navigate the “changing dynamics of the global battery market and with legislation such as the Inflation Reduction Act,” according to the release.

The company has been bulking up its U.S. EV partnerships in recent months. In July, GM and LG Chem signed a new sourcing agreement to supply the automaker with nearly 1 million tons of cathode active material by 2030.

Automakers and their suppliers across the EV market are working to bring more component manufacturing capabilities stateside in a bid to secure the Inflation Reduction Act’s EV tax credits. The law stipulates that over 50% of a battery’s components must be manufactured or assembled in North America starting in 2023, increasing 10% annually until 2028.

Days before LG Chem’s news, Panasonic announced it would source cathode active material from Nevada-based Redwood Materials. The components will be used in Panasonic’s planned manufacturing site in De Soto, Kansas.

LG Chem said the Tennessee site was the “best choice” given its proximity to key customers and easy transportation of raw materials. The company said it envisions the site acting as a “supply chain hub” for material and recycling partners to work together to supply customers.

The new facility will incorporate advanced production technology, enabling it to produce 10,000 tons of cathode material per line, according to the release. LG Chem also claims the factory will be entirely powered by solar and hydroelectric power.