Manufacturing construction continues to boom in the U.S. Construction spending in the industry continues to rise, reaching just over $236 million in October 2024, up 16.6% from the year before, according to the U.S. Census Bureau.

Money continues to flow in the wake of the CHIPS and Science Act and Inflation Reduction Act, with companies like Tesla, Samsung and Hyundai investing billions of dollars in mega construction projects across the country for semiconductor and clean vehicle factories.

Here are some of the biggest manufacturing construction projects to watch for in 2025.

Tesla

Products: Semi-trucks and batteries

Investment: $3.6 billion

State: Nevada

Timeline: Estimated to begin pilot production by late 2025, full production 2026

Nevada, already home to Tesla's first factory, is set to host another mega project with the construction of two new manufacturing facilities. Spanning 4 million square feet, the project includes a factory to produce electric semi-trucks and a 100-gigawatt-hour factory for Tesla's 4680 battery cells.

VP of Vehicle Engineering Lars Moravy said during an October 2024 earnings call that the project is “progressing swiftly,” having spent all capital funds for the project. Full production will begin in 2026 and ramp throughout the year, Moravy said on the call.

Hyundai and LG Energy Solution

Product: Electric vehicle batteries

Investment: $6.3 billion

State: Georgia

Timeline: Estimated to begin production by late 2025

Hyundai Motor Group and LG Energy Solution launched a joint project in 2023 to build an electric battery facility as part of Hyundai’s manufacturing campus in Georgia.

The facility could supply batteries for 300,000 EVs per year, which is the current projected output of the adjoining assembly plant. It is estimated to create 3,000 jobs.

The project is part of a larger $7.6 billion investment from Hyundai in the state. In June, the automaker announced that the first vehicle built at the EV plant would be the 2025 Hyundai IONIQ 5. Production at the factory began in October, the AP reported.

Samsung Electronics

Product: Semiconductors

Investment: $17 billion

State: Texas

Timeline: The first factory is expected to be operational in 2026 and the second in 2027

Boosted by $6.4 billion in funding from the CHIPS and Science Act, Samsung Electronics is building two factories producing four and two-nanometer chips, along with a research and development facility and a packaging fab in Taylor, Texas.

The project is estimated to create at least 17,000 construction jobs and more than 4,500 manufacturing jobs.

Samsung is planning massive investment in Texas, announcing its intent in 2022 to build 11 semiconductor plants worth $191 billion.

Panasonic

Product: EV batteries

Investment: $4 billion

Location: Kansas

Timeline: Slated to begin production at the end of March 2025

Panasonic Energy is building its second EV battery facility in the U.S., following the Panasonic Energy of North America facility in Sparks, Nevada. Located on a 300-acre site in Kansas, the new facility marks the largest economic development project in the state’s history.

The facility will expand the production of Panasonic’s 2170 lithium-ion EV batteries, with an expected initial annual production capacity of 30 GWh. The expansion is estimated to increase Panasonic Energy’s global capacity by 60%. In March, Panasonic signed a supply deal with H&T Recharge for lithium battery cans. As part of the deal, H&T plans to implement four new production lines at Panasonic’s Kansas plant.

Taiwan Semiconductor Manufacturing Co.

Product: Semiconductors

Investment: $12 billion

State: Arizona

Timeline: Expected to begin production in the first half of 2025

TSMC has announced investments of up to $65 billion in Arizona, the largest in the state's history. The company is building three semiconductor fabs, creating thousands of construction and supply jobs in the region.

After some delays, the first fab is estimated to begin production in early 2025, while the second plant is slated to open in 2027 or 2028. In November, the Commerce Department finalized $6.6 billion in CHIPS and Science Act funding for the project.

Ford and SK On

Product: EV batteries

Investment: $5.8 billion

Location: Kentucky

Timeline: Slated to begin production in 2025

Ford Motor Co. and SK On are collaborating to build up to three EV battery manufacturing facilities, capable of producing over 120 gigawatt hours annually. The facilities aim to supply batteries for future Ford and Lincoln EVs, supporting the automaker’s goal of achieving a global production rate of 2 million EVs annually by the end of 2026.

Spanning 1,500 acres, the project is expected to create over 5,000 construction jobs and up to 7,500 operations roles once fully operational. The project received a boost in December when it finalized a $9.63 billion loan from the Department of Energy.

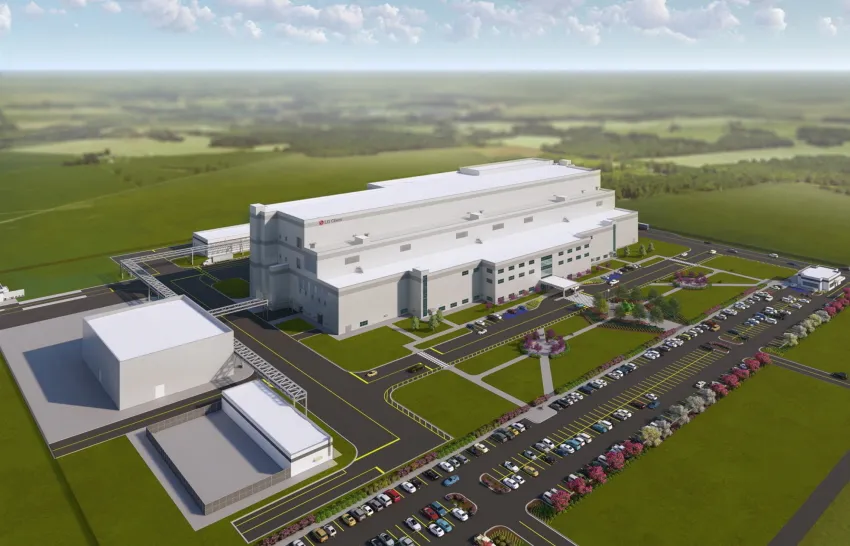

LG Chem

Product: Cathode

Investment: $3.2 billion

Location: Tennessee

Timeline: Estimated to begin production by the end of 2025

LG Chem is building a large-scale U.S. battery cathode plant with a production target of 120,000 tons of cathode material annually by 2027. The output is expected to power 1.2 million EV batteries. The company broke ground on the plant in December 2023 in Clarksville, Tennessee.

In November 2024, LG Chem signed a multi-year supply agreement with Exxon Mobile for the company to supply the battery component maker’s upcoming facility with 100,000 metric tons of lithium carbonate.